Pump Programming

How do I get a laboratory pump to do…. Your questions answered here.

Viscosity definition

Viscosity is a measure of the thickness or resistance to flow of a liquid or a fluid. It is a dimensionless quantity that is defined as the ratio of [...]

Book Mention

Biomedical Applications of Electrospinning and Electrospraying This publication mentions SyringePumpPro as an example of the software that can be used to control syringe infusion pumps in Electrospinning and [...]

a programming aid for Matlab and Labview

MyLabVIEW logo A lot of pumping applications use Matlab or ?abview as the control software. Why write ?abview? When I mean L abview? Because they (>abview wrote [...]

Two dependent gradient flows

Does SyringePumpPro do gradient flows? Does SyringePumpPro do dependent gradient flows? Gradient flows. gradient flows are not made by SyringePumpPro. They are made by the user programming the pump [...]

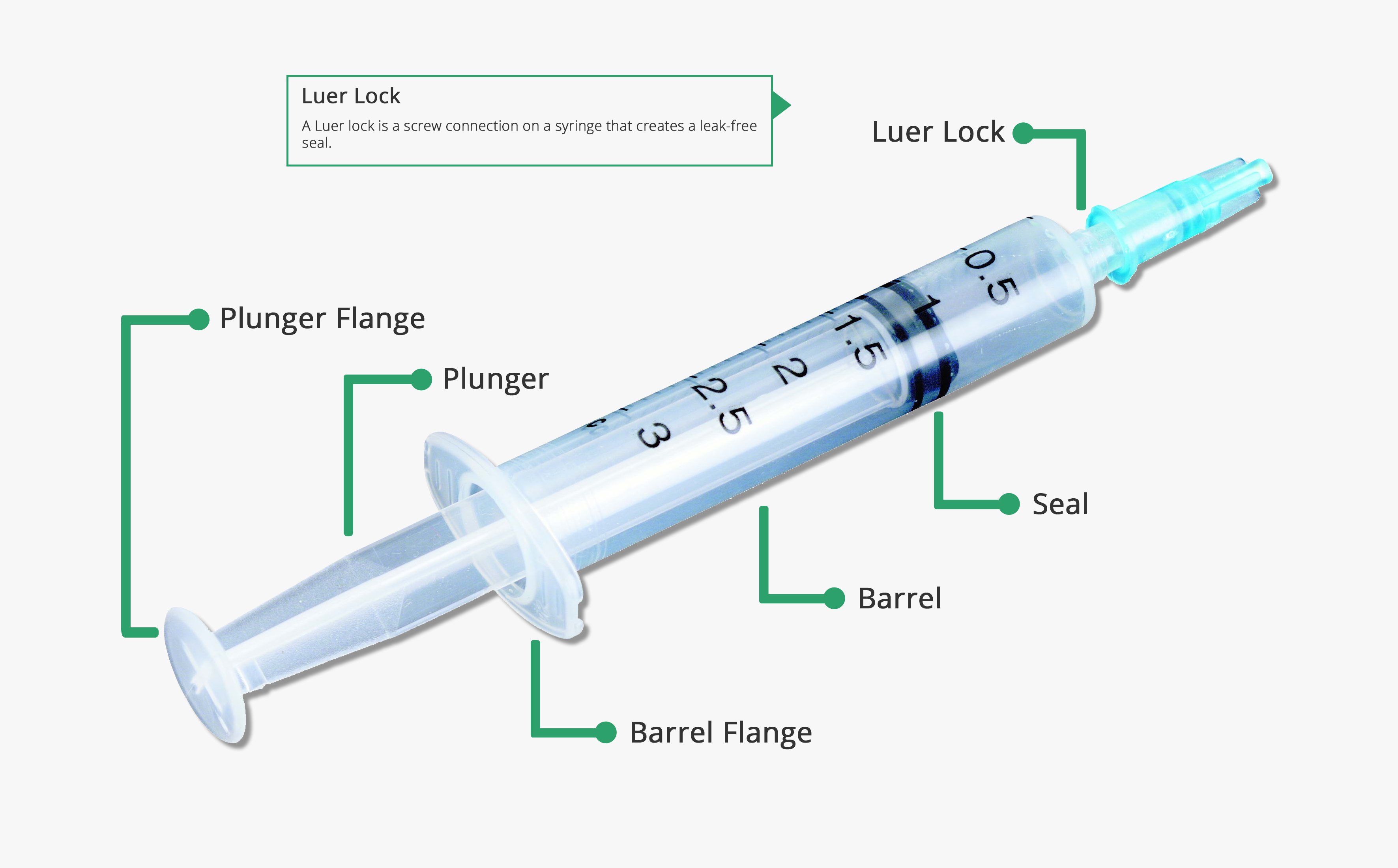

Parts Of A Syringe

Part Name Definition Plunger Flange The Plunger Flange bears the load of whatever is pushing the plunger. That might be your thumb or a [...]

Pump Programming Triggers

What is a Trigger? A trigger is something usually an electrical signal that is used to get a pump to change it's pumping action. Simplest example is the use of [...]

Meet the new look New Era Pump Family

New Era Pump Systems are entering a newer era! First we have a name change to New Era Instruments hinting at a broadening of their product range in [...]

New Era Pump Systems Inc

"The New Era Pump Systems, Inc. programmable syringe pumps provide an affordable solution to your sophisticated dispensing and flow control applications. Our syringe pumps offer the best value on [...]

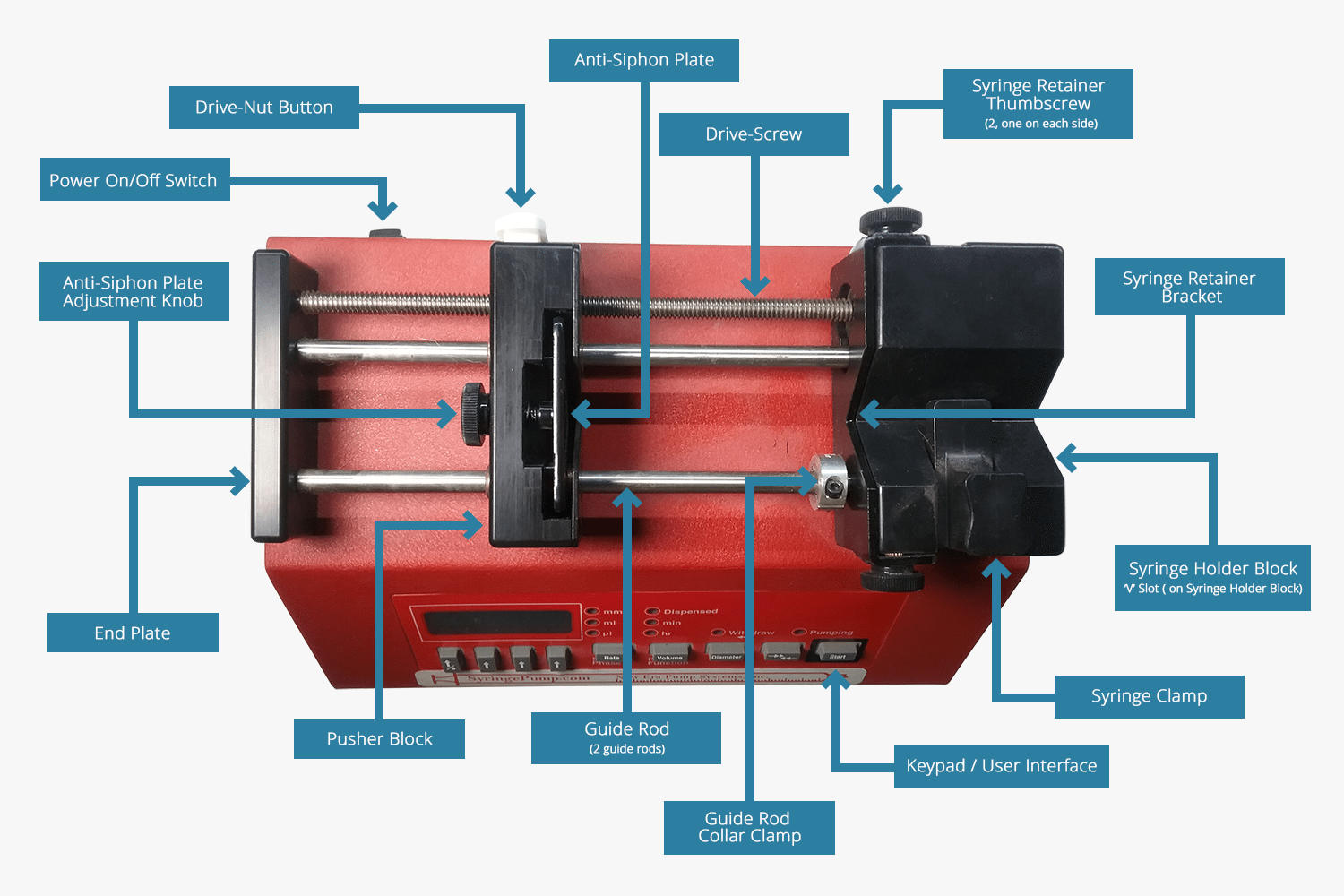

Parts Of A Syringe Pump

Diagram and brief explanation of a the parts of a syringe pump, and their purpose. Part Name Description and Purpose Anti-Siphon Plate Adjustment [...]