Pump Connectivity

This page deals with pump to computer connectivity issues. Many commonly reported issues and how to fix them are covered here.

Make your own pump cables CBL-PC and CBL-NET

Can you make your own pump cables? YES! – you can and this page contains the instructions on how to do it. To most people reading this page [...]

Multiple Pumps – Synchronization

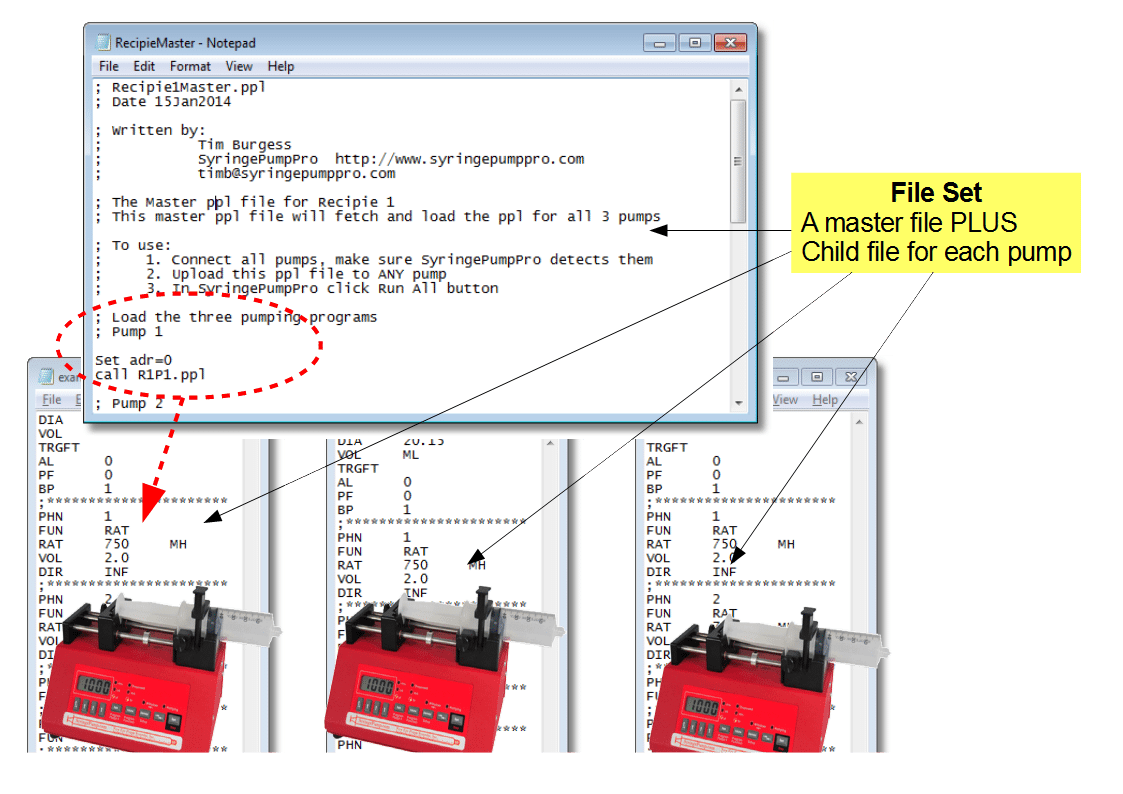

Good/Bad - Um? Depends what your looking for. I'd prefer simple sync and complex sync. The master ppl file setup - I love. Each pump's code is a separate file [...]

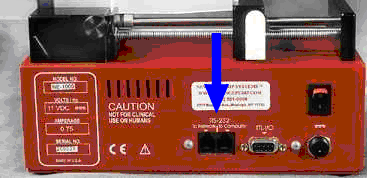

How to change the pump address

How Do You Change The Pump Address? READ THIS FIRST - IT's important!All pumps come from the factory configured as address 0. If you network 2 or more pumps without [...]

How far away can pumps be from the computer?

Often pumps and the computer controlling them need to be separated by some distance. This is found in a lot of applications where operator safety is a concern and [...]

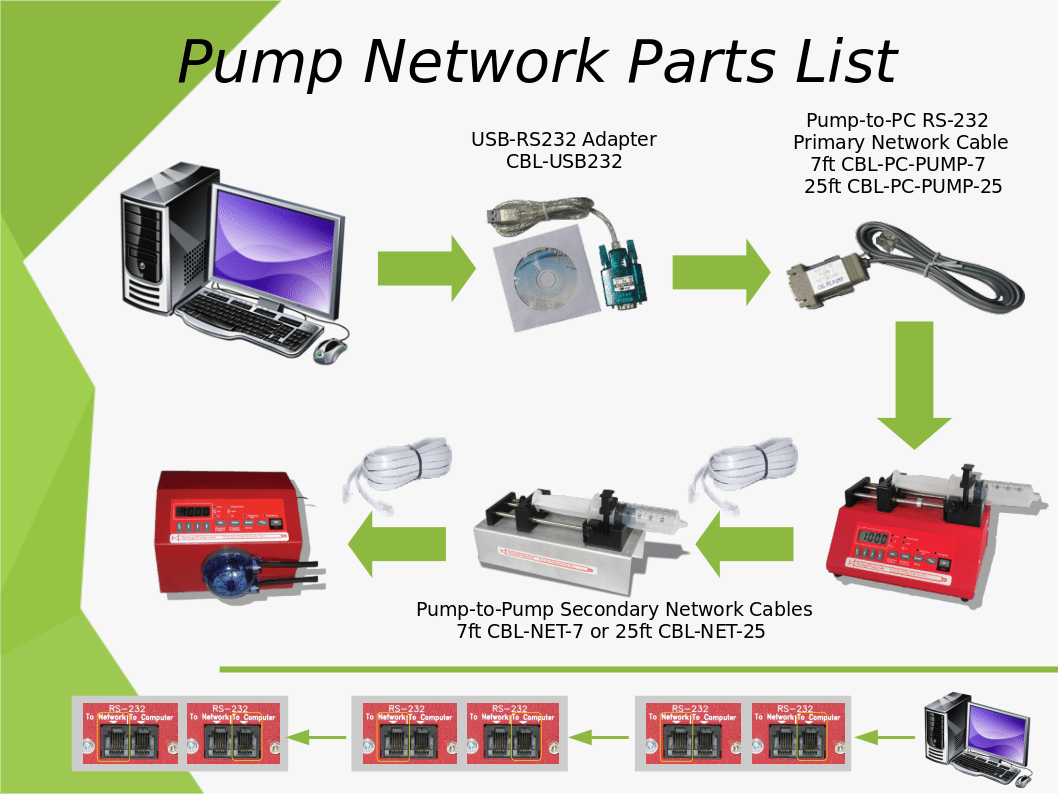

Pump Network Parts List

What cables and things do your need to connect your pumps to your computer? Here's the items you need. When one or more pumps are connected to your computer, [...]

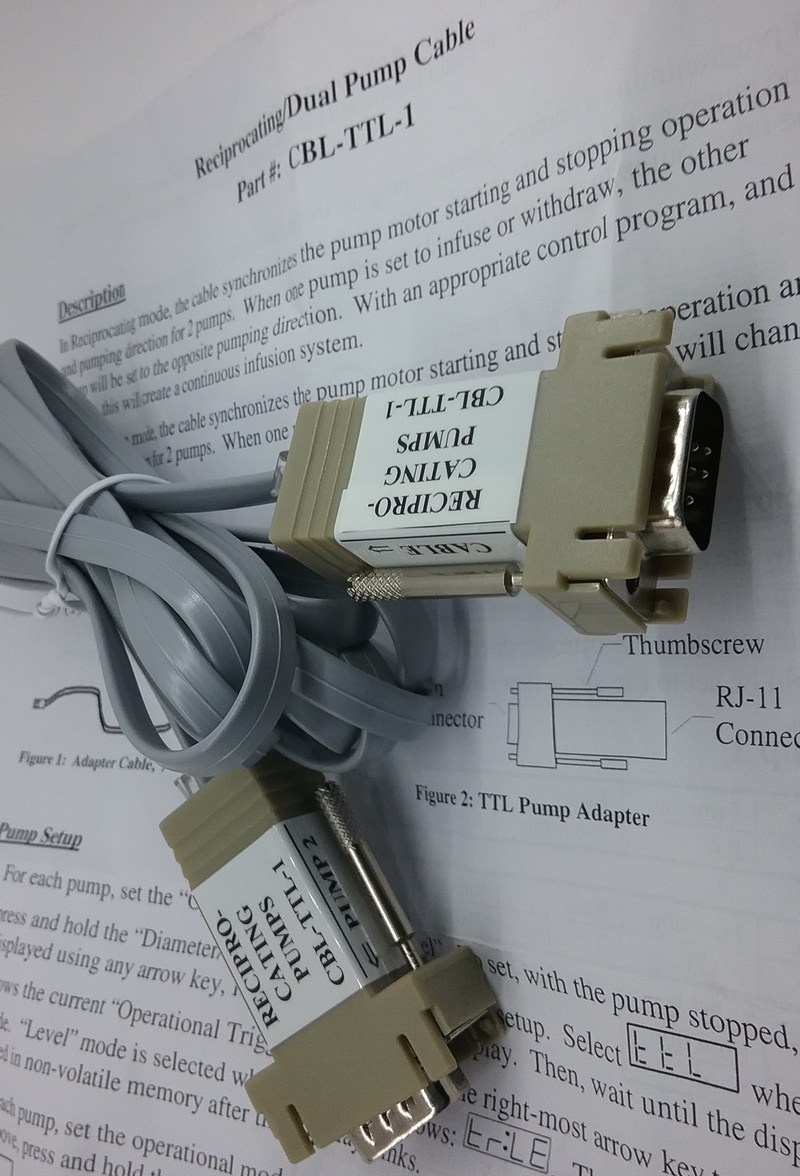

Cables

There are several cables that go with your pumps. The following table is a list of all the cables, their part numbers and their description and usage. Are you looking [...]

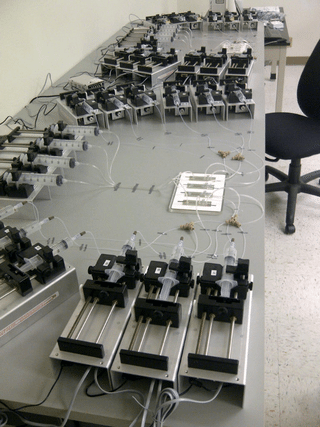

More than one pump at a time

32 pumps one SyringePumpPro I am often asked Can you connect more than one pump? Can you mix manufacturers? Can you mix pump models? Can you mix syringe [...]

Different models and brands at the same time

I get asked this regularly - can you mix and match pump models, and manufacturers. Yes. I do it every day. My pumps have come from all over, they are [...]

Making Pump Connections

Let's talk for a moment about how the pumps are connected. An understanding of this will help you diagnose communications problems with your pumps. The pumps are connected in [...]