Laboratory Pumps

NE-500 with Harvard Metal Syringe Loaded

The term laboratory pumps is a general term referring to pumps used in laboratories. Whilst the term covers all the pumps talked about on this website, it also might include vacuum pumps, pressure pumps, other kinds of fluid dispensing systems.

This site is primarily concerned with a subset of these pumps programmable laboratory pumps which can be used to generate a controlled or wave shaped fluidic flow. If you need to control your fluid flow – your looking in the right place!

Syringe Pump

You will find as you look around that a syringe pump is referred to by several names:

You will find as you look around that a syringe pump is referred to by several names:

- Syringe Pump

- Syringe Infusion Pump – so named because they infuse fluids. Some of them withdraw fluids too.

- Syringe Driver – because it’s a machine that ‘drives’ the syringe plunger. Can become confusing if you are familiar with computers where a driver is a piece of software that is associated with a hardware device.

- LabVIEW and Matlab users sometimes use the term Syringe Driver for a special module that interfaces with syringe pumps from those environments. In their case it is a software driver of sorts for their pumps.

- Generically as a laboratory pump.

Syringe pumps are named because they generally operate with a syringe mounted in a computer controlled mechanism that drives the syringe to deliver fluid.

Peristaltic Pump

PeriPumpONE

A very popular and commonly found laboratory pump is the Peristaltic Pump. Peristaltic pumps use an entirely different pumping action to syringe pumps which means there are some benefits and some disadvantages compared to the syringe pump.

Peristaltic pumps move fluids in a flexible hose kneaded by rollers turned by a computer controlled motor.

Some Peristaltic Pump Features

- Deliver consistent volumes and are easy to keep sanitary (no cleaning of the pump, insert a new tube).

- Replacing tubing prevents sample contamination. Handy where pump is transferred from site to site. E.g. water sampling in different location. Replace tubing for each location – no sample contamination.

- Can safely pump flammable liquids – the fluid only comes into contact with the tubing and not the pump mechanism.

- The output pulses a little as the rollers squeeze and release the tubing. There is a small amount of suction (really small) when the rollers leave the tubing and the tubing expands after being squeezed.

- Constant repeatable volumes until the tubing wears out.

- Peristaltic action is ideal for work with blood cells as it wont shear them like conventional impeller pumps will.

Microfluidic Pump

SP1070-m microfluidic syringe pump

Microfluidic pumps are usually syringe pumps but provide much finer fluid flows. These are used in microfluidic applications typically where precise control very small volumes of fluids are pump into very small physical devices. Typically these have dimensions below 1mm in size.

Microfluidic devices are used in everyday appliances such as the print head in your ink jet printer.

More information about the Microfluidic pumps

Pressure Vessel

Pressure Vessels – an Alternative to a Microfluidic Pump

Pressure Vessels are an alternative way of providing microfluidic flows for some applications. In use the lid is removed and the fluid placed in the flask – typically 100ml in usable volume. The lid is then replaced and the flask then pumped up or vacated using a low pressure pump. Some applications just need a droplet formed and your pressure vessel might be a good alternative.

You might think – a pressure vessel has got to be much cheaper than a software controlled mechanical pump and you would be right! But! Pressure vessels cost about 1/2 the price of the microfluidic syringe pump, then you need to buy the low pressure lab pump to put pressure into the vessels. It’s not unusual to discover that the cost of a low pressure pump will make a syringe pump look cheap!

Other major differences:

- No software control. So forget your waveform flows, your controlled, timed and all other kinds of flows.

- A syringe pump can produce both positive and negative pressures – where as you need two low pressure pumps to produce the positive and negative pressures.

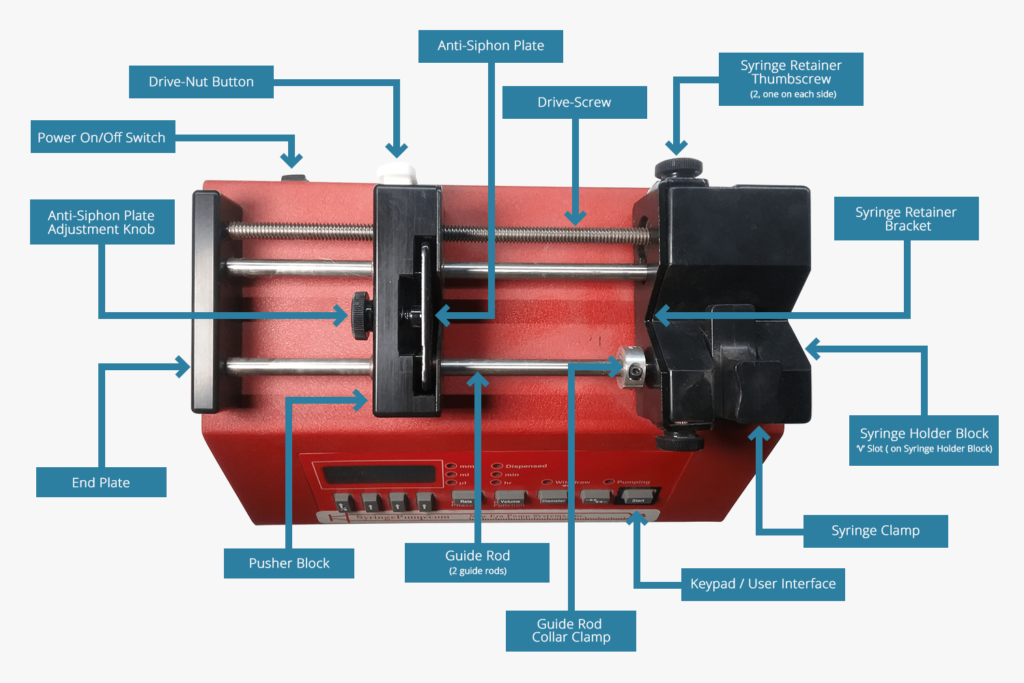

Parts of a Syringe Pump

Click the above diagram for a more detailed explanation of these parts and their function.

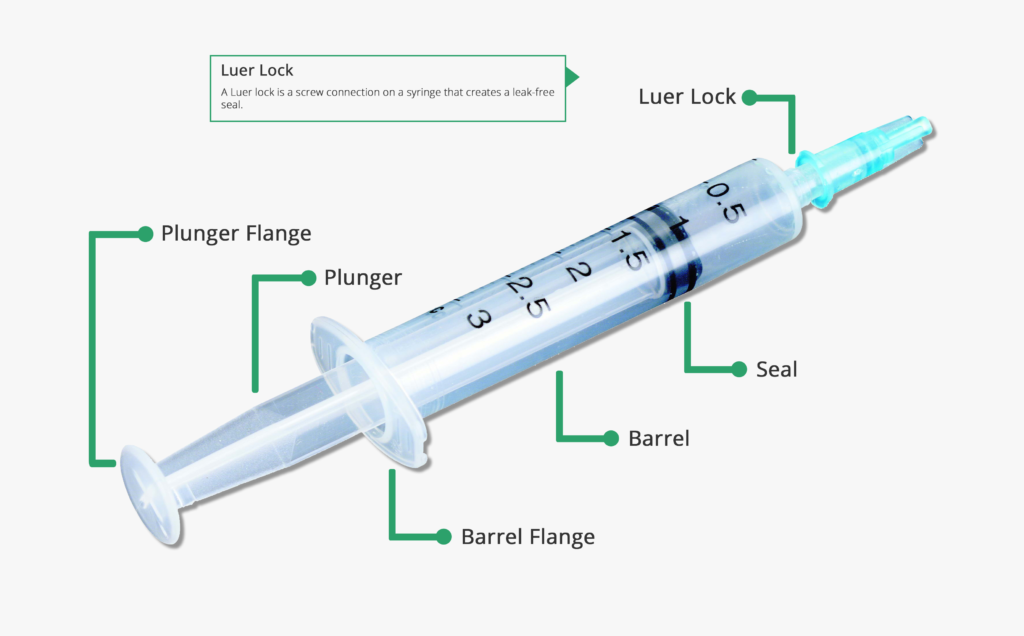

Parts of a Syringe

Click the above diagram for a more detailed explanation of these parts and their function.

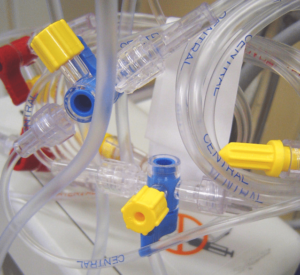

Parts of a Peristaltic Pump

Click the above diagram for a more detailed explanation of these parts and their function.

Tubing

Tubing is used to connect syringes to apparatus – including other syringes. It’s also used to provide the pumping action in peristaltic pumps. So there are several types of tubing. Your tubing selection will be affected by what you are passing through your tubing. You will need to consider the chemistry!

PVC Tubing – clear polyvinyl chloride and plasticizers that don’t have extenders or fillers in them. These are see through, with flexibility and dimensional stability.

Silicon tubing – Not clear, very flexible, available as Peroxide-Cured silicon, Tygon silicon (I use this with petro chemicals), Platinum-Cured Silicon. It has an very smooth inner surface which reduces particle entrapment and minimized bacterial growth. For use in high temperature applications.

There are many different tubing formulations, what you use will be basically decided by your application, Industrial grade, food grade, or chemical resistant.

OEM Pumps

An OEM pump is for use by Original Equipment Manufacturers. These pumps don’t have a user interface – no buttons and screens or indicator lights. They are meant to be buried inside a box obviously with the syringes exposed to the operator – or maybe not.

An OEM pump is for use by Original Equipment Manufacturers. These pumps don’t have a user interface – no buttons and screens or indicator lights. They are meant to be buried inside a box obviously with the syringes exposed to the operator – or maybe not.

These pumps will be computer controlled or have been pre-programmed to perform a sequence of pumping operations automatically.

OEM pump use example

One SyringePumpPro customer is working on a new exhibit for The International Sherlock Holmes Exhibition. It’s an interactive display involving blood spatters being made when you press a button. The blood is propelled using an OEM pump. The programming and development work has involved the use of my SyringePumpPro software.

Tip: Short on funds? OEM pumps can be purchased by anyone and they are a lot cheaper than laboratory pumps – but you need a piece of software to operate the pumps from your computer. That’s one of the uses for SyringePumpPro. Hey why not try it?

Dual Pumps – Continuous flow

Dual reciprocating pumps

Dual Pump sets are for the provision of accurate and continuous flow. In these systems pumps and plumbing are configured such that when one syringe is infusing the other syringe is withdrawing to refill itself. As the infusing syringe approaches empty the pumps switch functionality. The specially configured plumbing provides a single output and a single connection for syringe refill or source fluid.

Pump Accuracy

Accuracy in pumping terms is an expression of how close the fluid flow rate delivered by the pump matches the numerical value of the fluid flow you entered into or requested via computer.

Pump manufacturers will offer specification sheets declaring their pump’s accuracy. They are all pretty good.

Of all the different types of pump available, syringe pumps are recognized as the most accurate and repeatable devices for low volumes and low rate fluid delivery.

What effects accuracy?

Your fluid. The viscosity of your fluid can really effect the pumping accuracy.

Your plumbing. The length of tubing, the dimensional stability of the tubing (does it inflate like a balloon or is it rigid), the fittings (number and type) and the destination device can all effect the ability of the pump to output fluids. This can all be rate dependent too.

Your pump’s mechanics. A syringe pump with a non-rigid frame, and low quality components will have mechanical slack in it which will effect the rate at the start of pumping and at direction of pumping reversals.

Other things: the number of rotational steps the pumps drive motor has, in combination with the torque of that drive motor, the control of the motor drive electronics, any gear chain or belt drive mechanism.

Pump Flow Rates

Accurate flow and the range of flow rates achievable by a pump are a result of precise motor speed control. Motor speed in combination with the mechanical driving mechanism determine the maximum and minimum flow rates a pump may deliver. This in turn affects the range of rates a pump may pump over in combination with the syringe selection made.

Syringe selection range is limited by physical sizes of the syringe holding mechanism both the length of the pump stroke and the diameter both small and large that the syringe holding mechanism can securely grasp.

To know what flow rates a pump can achieve you should read the manufacturers specification sheet for your pump. This site has some specification sheets for download.

Pump Volumes

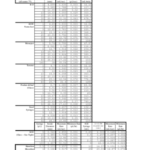

NE-1660-1860-1260-Rates-and-Specifications

The minimum volume that can be pumped is determined by the smallest diameter syringe that may be gripped by the pump’s syringe holding mechanism. In combination with the small syringe diameter, the lowest speed that the syringe pump can drive the syringe plunger at will determine the lowest volume that can be delivered. Most syringe pumps use stepper motors which operate in discrete steps. At the slowest and lowest volumes, these step motor step movements deliver in fixed increments.

However if the step increment is becoming an issue in your fluid delivery, chances are you have the wrong pump model, and perhaps need to consider a micro-fluidic specific pump.

Again the volumes your pump can deliver are specified by the pump manufacturer in their rates and specifications sheets.

What viscosity can be pumped?

A rough guide would be if you can pour it (even slowly) you can pump it.

The pump manufacturer has a simple explanation. Which is:

Syringe Pumps: Rule of thumb is if you can push or pull the syringe with your hand, then we have a pump that can push or pull the syringe. To reduce viscosity, you can utilize our Syringe Heater Kit. Warming up the fluid may reduce the viscosity.

Peristaltic Pumps: Rule of thumb is if the liquid freely flows by itself, the peristaltic pump can move your liquid.

My further explanation:

The amount of force the pump can deliver and the diameter of your syringe, tubing and all the equipment connected to the tubing are to be considered.

Syringe Heater and Controller

Some fluids won’t pour at room temperature and need to be heated to decrease their viscosity. To achieve this you can heat the syringes on your pumps. You then need to be sure that the fluid doesn’t cool in your apparatus and return to it’s higher viscosity.

This system will heat syringes and peristaltic tubing to help you pump those sticky gooey fluids.

- Syringe Heater and Controller

- Syringe Heater and Controller

- syringe and peristaltic heater installation

- Heater Kit

- Heater thumb

Pump Triggering

Modern laboratory programmable pumps can have their pumping programs triggered by external electrical signals. A logical 0 or 1 electrical signal can be sent to the pump and cause it to jump to a certain pumping phase. Some lab equipment will emit a logical 0 or 1 signal to trigger external items. A great example of that is another pump!

Modern laboratory programmable pumps can have their pumping programs triggered by external electrical signals. A logical 0 or 1 electrical signal can be sent to the pump and cause it to jump to a certain pumping phase. Some lab equipment will emit a logical 0 or 1 signal to trigger external items. A great example of that is another pump!

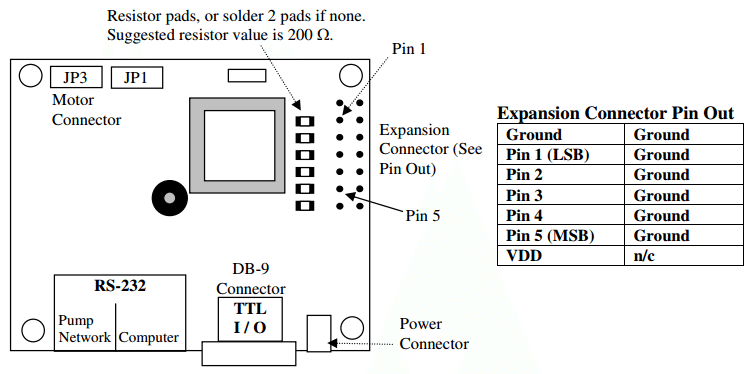

You can see in the diagram here the availability of electrical signaling in the NE-500 pump.

Foot Switch

Real Life Example

A fine example of pump triggering is connecting a foot switch to the pump.

A great example is the filling of ink cartridges by an operator. A pump program is written for a particular model printer cartridge. This is uploaded to the pump and set running with SyringePumpPro. When the operator presses on the foot switch the pump program dispenses the correct volume at a suitable pre-programmed rate to the ink cartridge thus guaranteeing the same fill for all cartridges.

Pump TTL Db9 Connector

The foot switch connects to the db-9 connector on the rear of the pump. In conjunction with a custom pump program (which you can easily create) allows an operator to trigger the pump to do some action – fill an ink cartridge. Simple to operate, precision dispensing, operator friendly!

Electrospinning

Taylor cone – Wikipedia

Electro spinning is a fascinating way of creating new materials by drawing very fine – extremely fine amounts of liquid at a high voltage probe. There is a fair bit about electrospinning on this site from the point of view of pumps and setting up. Many of my customers are working in this area.

To get started:

- See Spraybase electrospinning and electro spraying machines which use SyringePumpPro

- Read about the High voltage setup

Pump Manufacturers

Researching pump manufacturers? There are several mentioned on this site.

Computer Control

The pumps featured on this site are all capable of being connected to a computer. This can be for real time calculated flow changes or for pump monitoring and uploading of pump programs, testing of pump programs, and stop/start operations. As pictured here you need a computer to run SyringePumpPro, some cables and your pumps. It’s easy to setup, if you run into problems you can contact me and I will help you get started.

The pumps featured on this site are all capable of being connected to a computer. This can be for real time calculated flow changes or for pump monitoring and uploading of pump programs, testing of pump programs, and stop/start operations. As pictured here you need a computer to run SyringePumpPro, some cables and your pumps. It’s easy to setup, if you run into problems you can contact me and I will help you get started.

You can get an idea of some of the possibilities by watching the SyringePumpPro Tour Video.