Microscopes Controlling Your Pump – How do you do that?

This application note is for microscope owners who wish to pump fluids under the control of their microscopes. There are a number of reasons they wish to irrigate slides ranging from simply wetting their sample over time, applying solutions whilst they observe the effect on cells and small creatures, or to watch micro-fluidic level interactions.

This application note is for microscope owners who wish to pump fluids under the control of their microscopes. There are a number of reasons they wish to irrigate slides ranging from simply wetting their sample over time, applying solutions whilst they observe the effect on cells and small creatures, or to watch micro-fluidic level interactions.

Typical Flows Required

As a broad statement, microscope owners tend to want to create long term small flows or periodic washes or flushes. The flows are usually not complex – a single rate and volume but triggered by their viewing activities. Most commonly only a single pump is controlled.

More Than One Punp?

If your microscope only has the single digital output signal, and you wish to use more than one pump, you will need to adopt a pump control strategy. There are two – the all pumps at one time – parallel control strategy and the Daisy Chain strategy where a pump signals the next pump when it has finished it’s infusion. I would have liked to call this the serial strategy but I want to avoid using the word serial here – because well, we have a serial port involved.

Parallel Strategy

All pumps are wired to receive the same digital input on their foot-switch input pin, and then each pump’s pumping program (PPL) is written as though it were the only pump involved – ie a pump will pause for a length of time to allow another pump to deliver it’s flow and then infuse it’s own rate and volume. These pause times are easily calculated.

Multiple pump file sets

Be sure to use SyringePumpPro’s pump recipes method to upload the individual pump’s PPL files as a set – to guarantee pumps all receive the correct pump program each and every time.

Daisy Chain Strategy

Used to deliver a series of solutions not one solution with different rates and volumes.

This strategy refers to the fact that the first pump is connected to your microscope and the foot switch input of the pump. Then a digital output of the first pump is then connected to the digital input of the second pump.

In this strategy the first pump delivers the first flow then sends a trigger signal to the second pump.

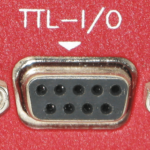

Pump TTL Db9 Connector

Connecting The Pump and Microscope

To control a pump from the microscope, owners arrange a digital signal line from the microscope to the digital inputs on the pump. This signal is then used by the program in the pump to stop/start flows or signal a change in rates. Think in terms of the microscope signaling the program in the pump to change the pump’s action – my software comes along for the ride monitoring your pump’s actions, as you develop your solution and as a monitor for operators when they use the microscope.

This is a simple plugs and cables issue. Identify your microscope’s digital output. Make sure its a ttl or logic signal style of output. 0-5Volts. Wire that to the pump’s foot switch input. Now all you need to do is work out whether your trigger signal is a rising or falling edge (the folks I talk too all have falling edges) – either way – you can configure the pump to deal with the different types of triggers.

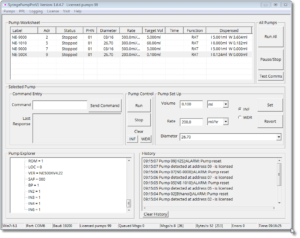

Run Time Monitoring and Control of Pumps

This is where SyringePumpPro can talk to the pumps over the serial port (see I knew that would come up) and show you what the pumps are doing. You can also interrupt one or more pumps, or start and stop all the pumps synchronously using the RUN and STP buttons on the SyringePumpPro control panel.

This is where SyringePumpPro can talk to the pumps over the serial port (see I knew that would come up) and show you what the pumps are doing. You can also interrupt one or more pumps, or start and stop all the pumps synchronously using the RUN and STP buttons on the SyringePumpPro control panel.

What Problems Arise?

Watch out for pump communication problems – if your microscope is connected to the same PC we can see a little conflict between USB-RS232 adapters when more than one is used. Don’t rush to use PCI serial cards to solve that problem – again the cheaper cards don’t make your life any easier.

More than One USB-RS232 Device

This is common – the microscope or the camera already requires a USB-RS232 device, so we need a second one for the pump control circuit. Some and I must emphasize some, USB-RS232 devices come with driver software that sucks. They are usually purchased for bargain price. The driver software assumes that there will only ever be the one device, so plugging in a second device leads to one or more of them not working properly.

This is common – the microscope or the camera already requires a USB-RS232 device, so we need a second one for the pump control circuit. Some and I must emphasize some, USB-RS232 devices come with driver software that sucks. They are usually purchased for bargain price. The driver software assumes that there will only ever be the one device, so plugging in a second device leads to one or more of them not working properly.

Confession: My SyringePumpPro also doesn’t help because it assumes that the first USB-RS232 device is where the pumps are – it’s only trying to help – really. So the trick here is to make sure that the pumps are on the first detected USB-RS232 device. The problem stems from first came the other device for the camera or microscope. Then along came the pumps and their second device.

Solution: Disconnect all USB-RS232 devices. Set up the pumps and SyringePumpPro. Now do the other device. Easy in the end!

Got a microscope related tip? Share it!!