Buying Used Lab Pumps

I have purchased most of my pumps via Ebay. I don’t think I have purchased more than one pump per Ebay vendor. I must take this moment to say I have not had any real problems doing this. I have, as you will read below, purchased faulty pumps unknowingly. I prefer to think that this is because in most cases the vendors know nothing about the pumps they are selling. Most of them simply apply power and say it seems to turn on.

NOTE TO VENDORS

Provide better sales information – please!

- Follow my Reset Your Pump video – it’s very short. Then power the pump up and press the run button – the pump will run – and you can say that it ran.

- Locate the pump make and model in my supported pumps pages and link there – buyers will be able to get the manual for the pump you are selling, and in some cases chassis drawings too.

(Pump buyers – If their ads don’t say it runs – direct them to this page, if they still say powers up… consider another pump.)

Other places you should be able to find used pumps are foreclosure sales. I think most of my Ebay purchases are actually business closure disposals that a seller has purchased and then is reselling. Use scientific equipment auctions – there are websites for this, would also be a great starting place.

Pro Tip

Before you start make sure you know the pump’s normal retail price – in my experience that will immediately eliminate maybe half of what’s for sale on ebay.

How to Evaluate a Pump

What things should you look for when you evaluate a pump?

Look at the price last! I have seen pumps that are either really really old or in shocking condition, with near new price tags. Often if you keep your eye on the auctions you will see the items relisted over and over, often at the same ridiculous price. Some come down eventually. I would suggest don’t buy then either – it seems to speak volumes about the seller. I haven’t bought a second hand pump at near new prices yet – but I have communicated with the sellers on the auction – my opinion is steer clear. You’re not getting any warranty if you purchase so pay less rather than too much.

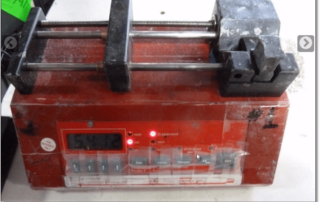

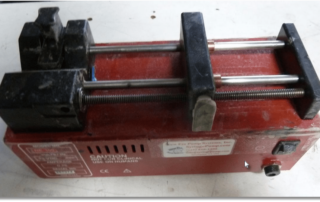

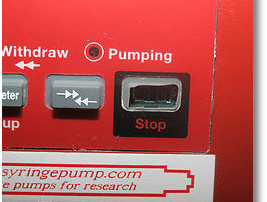

Take a long look at the photos above

You can click your mouse on the images, click and they will enlarge.

All of these pictured pumps have obvious problems,

General filthy condition

Doesn’t suggest the owner took much care. Cleaning and maintenance were not done – so this sort of pump will have considerable wear. Will likely be a staller or was worked to near death and is now being sold off. Stay away!

Extreme Wear – by Humans

Some of the photos above show mechanical wear and poor condition in the drive mechanism – dirty color is a clue and others show human wear – broken buttons and all the paint missing from the case immediately under the front panel buttons. Broken buttons and paint wear tend to show a lot of use by humans and they wont be SyringePumpPro owners – I bet. Imagine the hours it takes to wear through paint and break off buttons tops – could be a sign of a bored operator and bored operators might not have been caring for the pump…

Broken buttons

In the photo on the left – can you see the missing Program/Phase # button? This is an easy repair – if you can get the spare part.

These buttons are all on a rubber membrane, so you cant (well easily) replace a single button – you have to replace the entire membrane of all buttons. This is actually not hard to do, taking only minutes of your time.

The risk of your repair not working is quite low. BUT where do you get another membrane? You should also know that the membrane doesn’t seem to have changed for years and is the same between models – even peristaltic / syringe pump membranes would seem to be interchangeable.

LCD Segments that don’t work

This problem is limited to the LCD display which needs changing. But you will be de-soldering and soldering. Not a lot of folk are comfortable soldering. You might have access to someone else who can solder. But to gain a new LCD display you would need to buy another pump. Why not just buy the other pump and be done with it? Don’t over look the fact that if you get the pump cheap enough – you could buy a license for SyringePumpPro and simply use your computer to operate the pump – the LCD display can be ignored!

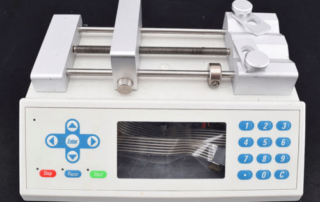

Missing LCD displays

Chemyx pump with missing lcd display

You know how this happened don’t you? Read the paragraph above if you don’t. From this photo you have no idea what other parts are missing. Leave that pump in the shop.

Getting Spare Parts

The pump manufacturers don’t offer spare parts, but offer repair at their distributor. So if you need spare parts you will have to buy another pump. So look for a real bargain pump that doesn’t work but has a visibly intact membrane – as much as you can tell from photos.

Buy a clean but cheap pump – any model. I purchased the pump pictured with broken button, and then purchased an NE-300 which is not programmable for a bargain price. I have used all sorts of parts from that NE-300 to make a few repairs.

How Old is the Pump?

The actual age of the pump – if it’s done no work – is not really a consideration. But pumps weren’t purchased to sit and do nothing. So what are the signs of pump old age?

The actual age of the pump – if it’s done no work – is not really a consideration. But pumps weren’t purchased to sit and do nothing. So what are the signs of pump old age?

- Filth – if it’s in poor condition – never cleaned and like this pump looks like it was used as a hammer – it doesn’t really matter if it’s only a week old. If you zoom in on the photo you can see the grime from the fingers that have been loading syringes. When was the last time you were in lab where people had hands that were grimy? This pump’s accuracy and reliability have been seriously compromised. Pumps are precision laboratory equipment – what kind of @#%!%@ does that to lab gear? Was that too strong?

- Look at the guide rods – they should be silver, shiny and the same color for their full length. The pump pictured shows bands of discoloration on the guide rods which indicates that this pump has done the same job day in and day out for a long long time. It is surely bored with life :-} There will be considerable wear through out the drive train – leave this pump alone. If you saw the listed price – you would have left it alone for sure.

- Look at the syringe clamping mechanism – look at the discoloration and wear there – it almost looks like the metal parts there have rounded with wear.

- See the drive screw. You can just make out fluff and muck and discoloration on the drive screw. This is normal but the other indicators above might suggest that these fluffy bits are actually filings coming of the nut block. Read more about nut blocks below in Unseen Faults and here’s a full description of nut blocks.

Pump Serial Numbers

At the time of writing this – new pumps are serial numbered around 300000. I wouldn’t buy a pump with a serial number much lower than say 250000. But if it was extra cheap and looking in great condition – a bargain is a bargain.

At the time of writing this – new pumps are serial numbered around 300000. I wouldn’t buy a pump with a serial number much lower than say 250000. But if it was extra cheap and looking in great condition – a bargain is a bargain.

Unseen Faults

What are the problems you can’t see and the seller’s don’t mention. Or tell me about the pump purchases where you were disappointed.

What are the problems you can’t see and the seller’s don’t mention. Or tell me about the pump purchases where you were disappointed.

Stalling

Many pumps have stall detectors. These are used to sense when the pump has bottomed out the syringe plunger. When the pump is driven but no syringe plunger motion occurs the stall detector let’s the pumps computer chip know and the chip stops trying to drive the plunger and protects the syringe, the mechanic, and the drive electronics.

When a stall detector fails – it reports a constant stall condition. The pump will run for seconds and then stop for no apparent reason.

Chewed out nut blocks

The nut block is a device intended to protect the mechanics and electronics from operating in a stalled condition. Some pump owners rely on the stall detector as a pump stopping mechanism – which is poor behaviour and invalidates pump warranties too!.

The nut block is a threaded component that rides the drive screw – after a lot of stalling it looses it’s teeth. Symptoms are low pressure.

Dead motor

Inside these pumps are a 3 phase stepper motor. This gives incredibly fine control over the lead screw’s turning motion. Sometimes – very rarely in my experience (it happened to me once) a single phase of the motor was no longer working. However I replaced the stepper motor with one from another donor pump – which only took minutes to do.

Dead Electronics Board

This has never happened to me. In my experience about the only time I ever hear of a dead electronic board in a pump, I am usually talking to an electro-spinner. In those cases the boards aren’t usually totally dead either – they act erratically – like you might if someone put thousands of volts up one of your connecting devices.