Syringe Pumps and Peristaltic Pumps are computer controlled mechanical machines. They get dusty – even in clean environments. These great laboratory devices cost a lot of money – so you should look after them by performing some pump maintenance for a long pump life time. Reliability and repeat-ability of pumping flows are important to manufacturing and scientific users.

Syringe Pumps and Peristaltic Pumps are computer controlled mechanical machines. They get dusty – even in clean environments. These great laboratory devices cost a lot of money – so you should look after them by performing some pump maintenance for a long pump life time. Reliability and repeat-ability of pumping flows are important to manufacturing and scientific users.

What are the Pump Maintenance items that you can do?

Most importantly keep your fluids away from your pump. If your plumbing weeps under pressure – fix it.

Clean all spills from the pump in an manner approved for the materials you are pumping.

Clean all spills from the pump in an manner approved for the materials you are pumping.

Oiling – How should you oil your pump?

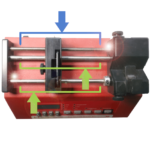

1 drop of oil at these points

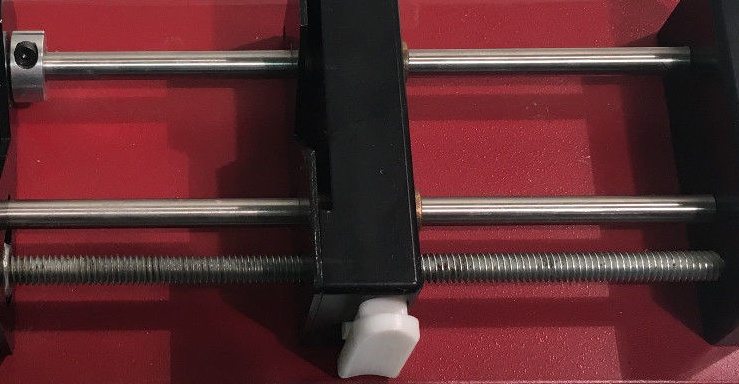

Guide Rod Close Up

Should you oil your syringe pump? Syringe pumps have a lead screw that is subject to considerable pressure forces. There is a nut block running up and down the thread on the leadscrew. There are two guide rails either side of the leadscrew as well, which if they become mechanically sticky will affect the pump’s performance.

The pump’s lead screw and guide rods, should be very lightly oiled when they look dry. Look for a slight oil sheen – if it isn’t there – lubricate. Make sure you clean the parts you oil first to remove any dust and other dirt from them. The lead screw can be difficult to clean.

- Use 1 or 2 small drops of light machine oil on the leadscrew (blue arrows) – one either side of the pusher is best.

- 1 drop on each guide rod (green arrows).

Lead Screw Up Close

Why more oil on the threaded rod? Pressure and surface area of the lead screw.

Be careful not to flood the lead screw or the guide rods as the excess oil will be squee-geed out to the ends of the lead screw by the nut-block assembly traveling back and forth. You might find that either end of the top of your pump will become oily. This will then spread across your pump as a fine film of oil.

Normal lead screw wear

Back to Pumps | Back to FAQs