Syringe pumps are supposed to automatically stop when they had reach the end of the plunger travel. This is called stall detection. There is stall detection circuitry which can see the high load on the motor and signals the computer in the pump to stop applying the driving force. This is to protect the tooth drive belt and syringe driving mechanism and of course the syringe itself from damage. Especially those tiny glass syringes the micro-fluidic people use!

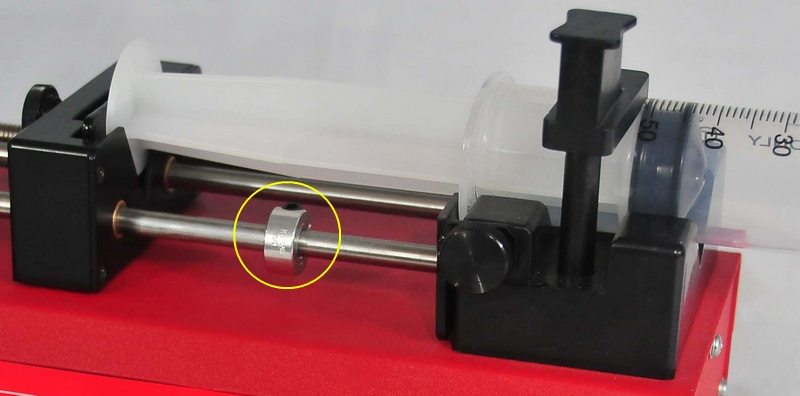

This end stop can either be the syringe clamp or the Guide Rod Collar Clamp.

These collars are used to set this end point to anywhere you wish on the plunger travel.

Some newer pumps (the NE-8000) for example, have two of these collars – one each to set the limits of both infusion and withdrawal travel. Te NE-8000 has a knob to adjust the maximum pressure to be reached by the pump.

If your pump wont stop when the pusher block hits the collar or the syringe clamp then you possibly have a faulty stall detector, or your drive nut can be stripped from repeated runing the pump until it hits these collars or the end block – in either infuse or withdraw directions.

Failed stall detection has a rubbery repeated thumping sound as the teeth of the rubber drive belt slip on the motor drive – slowly eating your belt.

How to fix pump stall detection

If your stall detector has failed, then your pump needs to be returned for repair. It might be a problem with your drive nut.

How to avoid stalling your pump

Start programming your pump to deliver set volumes that are smaller than the total volume of the syringe you are using. Once you start programming you will find a whole new world of pump functionality!